Overview:

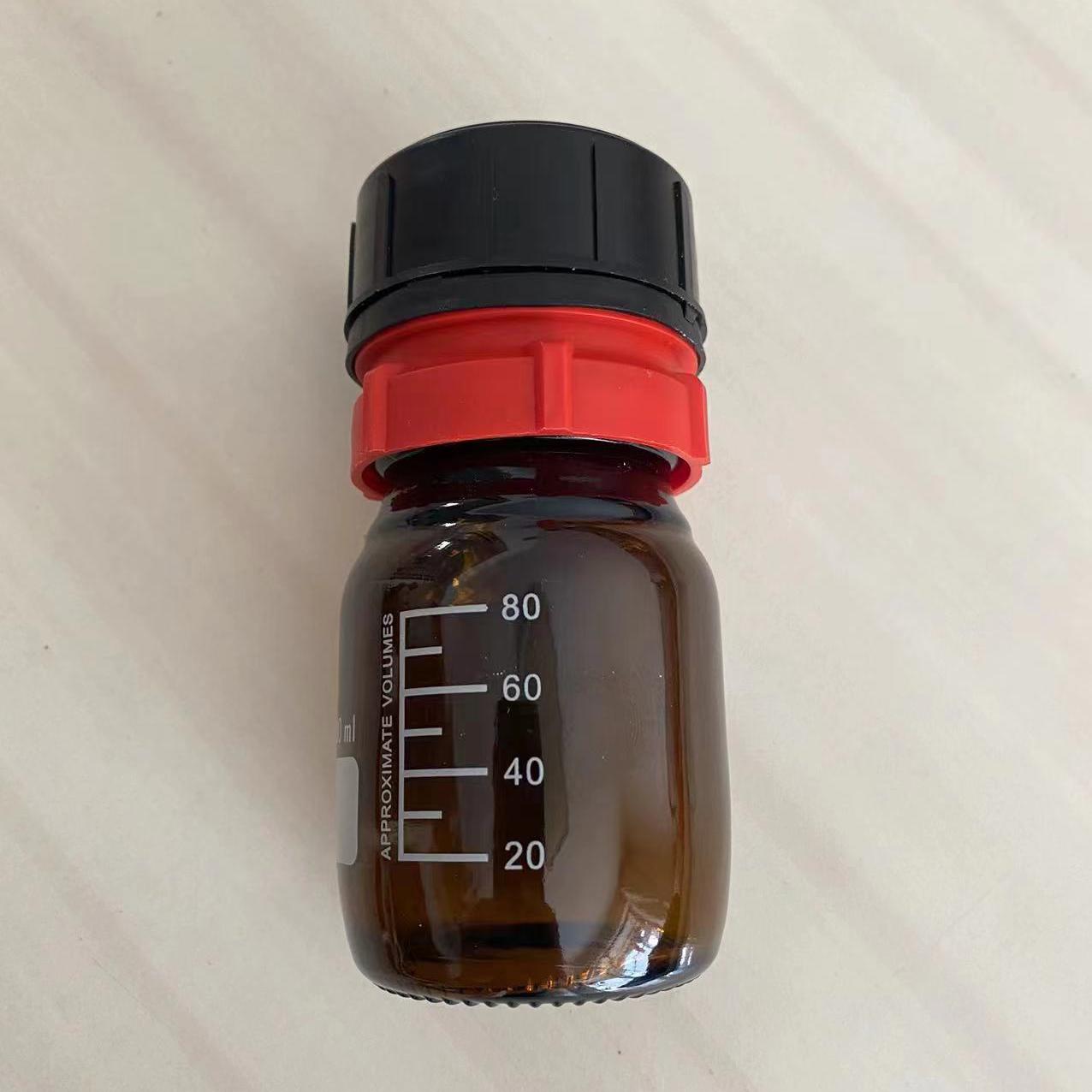

This product can effectively isolate moisture and oxygen in the air, and has good sealing performance, corrosion resistance, and can be reused. Thus to ensure the stability of liquid reagent product content. Applicable places include: high-end fine chemical industry, colleges and universities, pharmaceutical companies, laboratories, scientific research units, etc.

Main structure and characteristics:

1. Main structure: composite rubber gasket, high borosilicate glass bottle, double PP screw cap.

2. Product characteristics: the front and back of the rubber gasket is polytetrafluoroethylene, and the middle is composite rubber. The excellent chemical properties of polytetrafluoroethylene can resist all kinds of corrosion, and the composite rubber is better than the general rubber. The advantage of double-sided design compared with single-sided polytetrafluoroethylene is that it greatly reduces the leakage and corrosion contamination of needle residue during the use of the product. High borosilicate glass bottle than a general glass bottle expansion rate is low, high and low temperature resistance, good pressure resistance. The porous design of the inner cover of the double-layer PP screw cap effectively reduces the number of pinholes per unit area of the gasket, so that the force of the gasket is more uniform and the utilization rate is improved.

Problems and solutions in the process of use:

Compared with other ordinary packaging, the packaging of this product has a shorter listing time in China. From R & D and production to supporting the use of various groups, our company is a process of continuous discovery, solution, learning and improvement. At present, the product tends to be perfect. Composite rubber gasket is the top priority in this product, but also our key research and development object. According to the feedback of customers and users, it is found that the main sets of problems are leakage caused by lax sealing and leakage caused by non-corrosion resistance. In the process of extraction and use, the problem of liquid reagent splashing through the pinhole in the bottle is more prominent. Our company has done three times before and after the gasket replacement, the current third generation of composite rubber gasket can be a good solution to all the above problems.

The following is the picture and summary after the test of three generations of products (represented by A, B, and C respectively) : The rubber gasket is fully contacted with the specified reagent, and the performance of the gasket rubber is mainly tested.

The rubber part of the main body of type A is gradually dissolved, the polytetrafluoroethylene does not change, and finally the rubber disappears only two pieces of polytetrafluoroethylene.

The rubber part of the body of type B swelled and gradually cracked, and at this time it has lost the elasticity of the rubber. The reason for this result is that the polytetrafluoroethylene will not react with the reagent, and there is no change before and after the test. However, the reaction between the rubber part and the reagent leads to the swelling of the rubber, and the rubber part gradually loses its elasticity with the change of time, which is affected by the tension of polytetrafluoroethylene and makes the rubber slowly crack, and the cracking degree increases with the growth of time.

The main rubber of type C has swelling, but its swelling degree is significantly smaller than that of B, and there is no sign of cracking, still retaining the elasticity of rubber, and polytetrafluoroethylene has no change.

The above mentioned liquid reagent spatter problem in the process of extraction and use is that there is no change in rubber resilience after the reagent contacts with the rubber part. Type B can meet the packaging requirements of most of the liquid reagents on the market, so it has a wide range of use and a large amount. However, it cannot meet the packaging requirements of some special liquid reagents. Type C is the third generation gasket developed and produced by composite rubber, which has good resilience and can solve the spatter problem well.

With the development and progress of national science and technology, the types of reagents are gradually increasing and improving. There will be problems with development

In our company, we will provide as perfect a solution or product as possible according to the problems raised by the manufacturer and the user.